Application of Ultrasonic Coda Wave Interferometry for Micro-cracks Monitoring in Woven Fabric Composites

Abstract

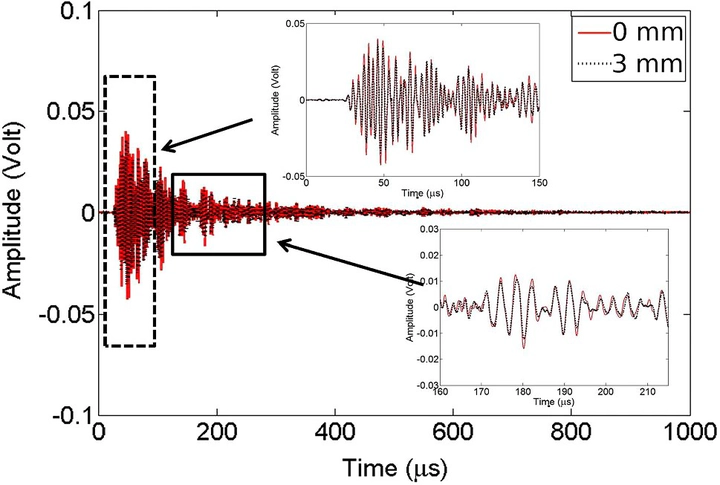

The consequences of a four-point bending test, up to 12 mm, are examined by emitting 1 MHz ultrasonic guided waves in woven carbon fiber reinforced polymer specimens, using coda wave interferometry (CWI), revealing a potential use for nondestructive evaluation. It is known that CWI is more sensitive to realistic damage than the conventional method based on the first arriving time of flight in geophysical, or in civil engineering applications such as concrete structures. However, in composite materials CWI is not well established because of the involved structural complexity. In this paper, CWI is investigated for monitoring the occurrence of realistic defects such as micro-cracks in a woven carbon fiber composite plate. The micro-cracks are generated by a four-point bending test. The damage state is stepwise enhanced by gradually increasing the load level, until failure initiation. The damage is monitored, after each loading, using ultrasound. It is demonstrated that CWI is a powerful tool to detect damage, even low levels, in the sample. Two damage indicators based on CWI, i.e. signals correlation coefficient and relative velocity change, are investigated and appear to be complimentary. Under significant loading levels, the normalized cross-correlation coefficient between the waveforms recorded in the damaged and in the healthy sample (reference at 0 mm), decreases sharply; this first indicator is therefore useful for severe damage detection. It is also demonstrated, by means of a second indicator, that the relative velocity change between a baseline signal taken at zero loading, and the signals taken at various loadings, is linear as a function of the loading, until a critical level is reached; therefore this second indicator, is useful for low damage level detection. The obtained evolution of the relative velocity measurement is supported by relative comparison to the evolution of the bending modulus in function of displacement. The relative velocity change exhibits the same evolution as the bending modulus with loading. It could be used to indicate when the material stiffness has decreased significantly. The research is done in the framework of composite manufacturing quality control and appears to be a promising inspection technique.